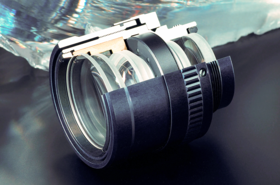

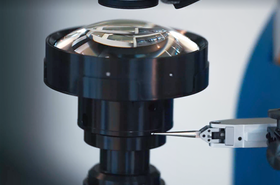

Mechanical components for precision systems

In-house production for maximum precision

PRODUCTION FOR ALL BATCH SIZES

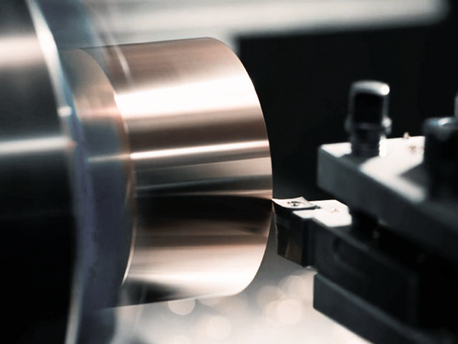

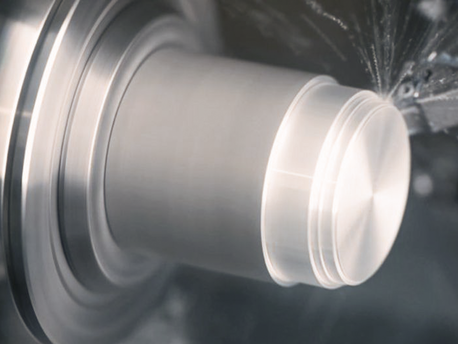

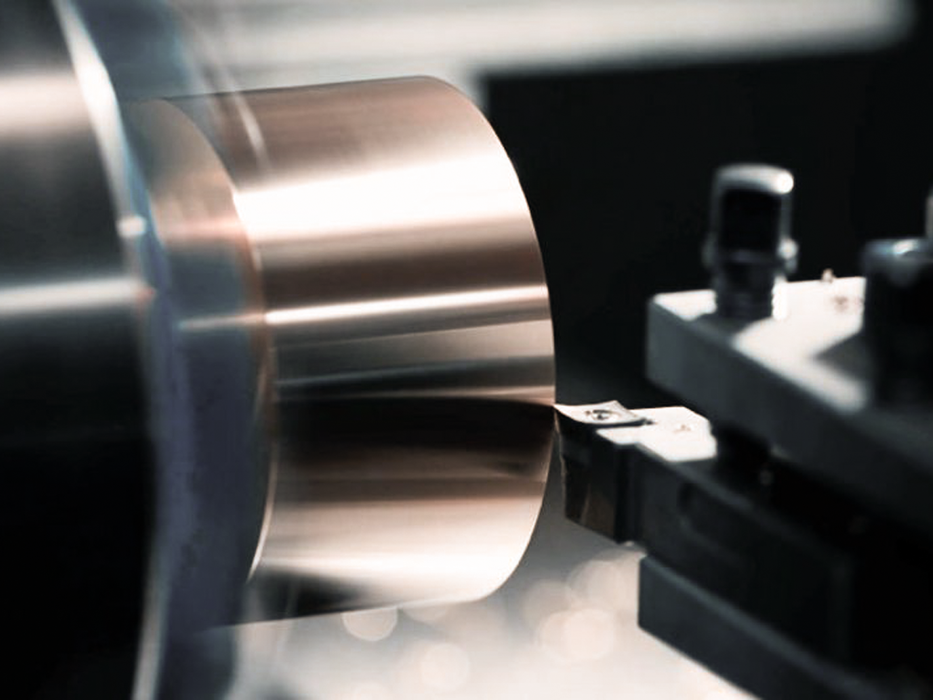

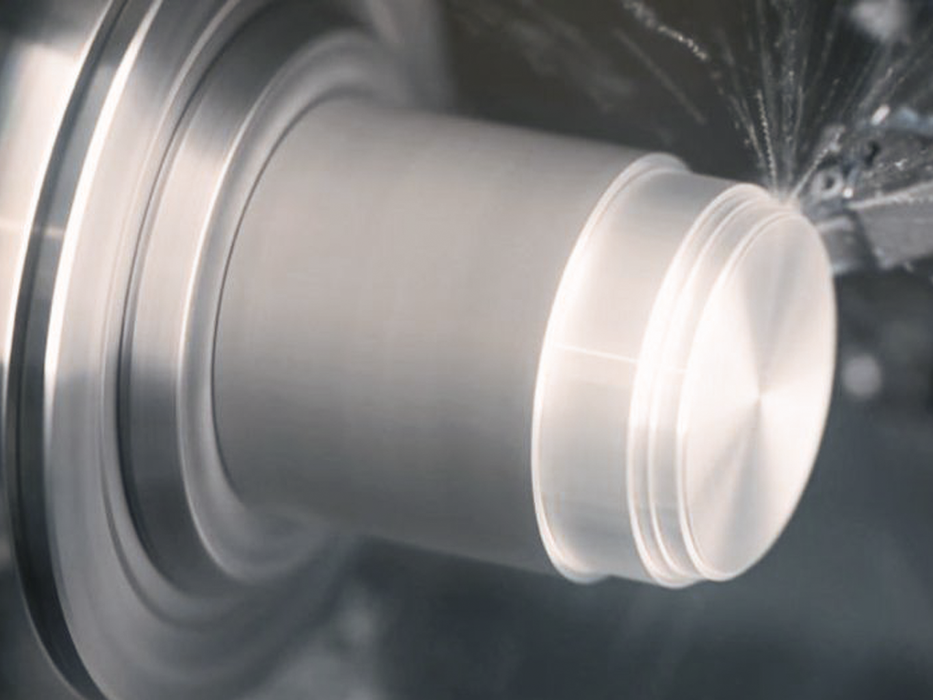

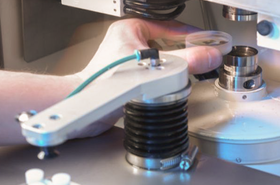

We manufacture the mechanical components for our optical systems in-house. Our specialized employees have access to state-of-the-art CNC machinery with turning and milling centers with up to nine axes. An innovative programming system allows the production of highly complex rotationally symmetric and cubic components with unprecedented efficiency. In addition, we have great expertise and sophisticated technical capabilities in the field of finishing, including blue pickling, anodizing, barrel finishing or glass bead blasting.

Our employees know what it means to manufacture high-precision mechanical components for optical systems. They use a special "feeling", which is also used by other manufacturers of optical assemblies.